Originally written by Rocky Rotella for the September 2011 issue of High Performance Pontiac Magazine. The article and photo gallery can be viewed

A note from Rocky: The Butler Performance Pro-Series oil pump is an excellent unit that we use in our own Pontiac engines. I highly recommend them for the reasons outlined in the story below. If you're interested in purchasing one for your build, Butler offers 2 versions: A 60 lb pump and an 80 lb pump.

An engine’s oil pump dispenses the pressurized lubricant that prevents opposing surfaces from contacting one another, carries heat away from certain areas, and maintains minimal valvetrain lash when running a hydraulic camshaft. Bolted to the block and residing deep within the oil pan, it operates so reliably that it could be the most disregarded component of any engine.

Contrarily, the oil pump may be the most critical component within an engine. Conscientious hobbyists closely monitor their Pontiacs’ in-dash gauges, knowing that most likely all is well within the engine if hot oil pressure doesn’t dip dangerously low at idle and pressure at normal cruising speed remains steady. If the pump can’t perform its task, it will not only lead to significant bearing damage or complete engine failure, but ultimately total engine destruction.

The traditional gear-driven Pontiac V-8 oil pump is a simple design that is quite reliable. Discontinued by Pontiac years ago, Melling Tool Company manufactures today’s replacements, and we spoke to a company insider about its Pontiac-specific offerings. We then contacted Butler Performance, a Pontiac performance leader, to gain a better understanding of high-performance Pontiac oiling requirements and learn more about its new Pro-Series oil pump. Here’s what we learned.

Pontiac Oil Pump Basics

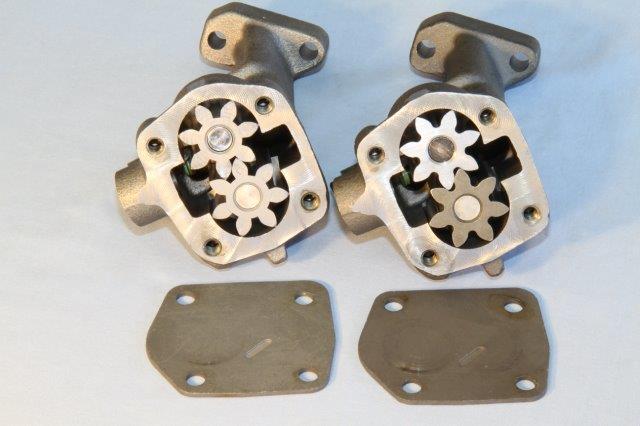

The Pontiac V-8 oil pump is a positive-displacement rotary unit that utilizes two spur gears to distribute pressurized oil throughout the engine. As the gears rotate, their teeth separate and creates a partial vacuum that draws oil into the pump body through the inlet pickup tube. Oil then fills the spaces between the gear teeth, where it’s carried to the output side of the pump and forced out through its discharge hole.

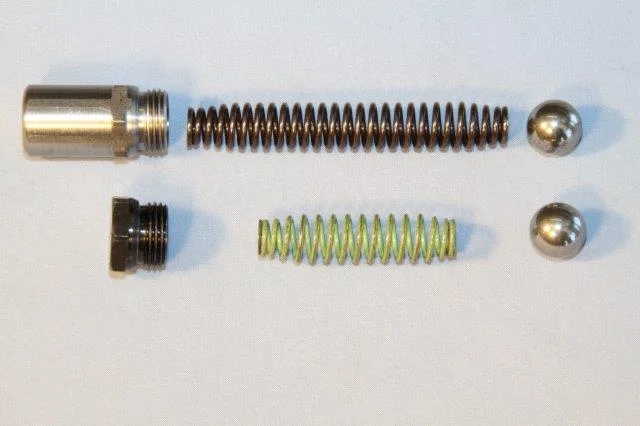

Pressurization occurs when discharge flow meets the resistance associated with forcing oil throughout the engine. Oil-flow volume increases along with engine speed, and a sprung ball-type bypass valve regulates maximum pressure. Once the preset amount of pressure is reached, the bypass valve’s check ball is forced off its seat, redirecting excess output flow back toward the inlet side of the pump.

Pontiac used three distinct oil pumps in its V-8 engines, and they are often referred to by approximate maximum pressure ratings of 40, 60, and 80 pounds per square inch (psi). The 40-psi unit is the easiest to distinguish by its 5⁄8-inch-diameter inlet opening, and it was commonly used in two-barrel and low-performance four-barrel applications. The 60- and 80-psi units feature a ¾-inch inlet opening for increased volume capacity. The 60-psi was most often used in 400- and 455-inch performance engines. The 80-psi pump, which is immediately recognizable by its longer bypass-valve nut, was used in the ’73-’74 Super-Duty 455 (and the non-production Ram Air V).

The oil pumps that Pontiac originally specified for its engines were very reliable and rarely troublesome. New replacements were available from dealership parts departments for a number of years. As certain part numbers were superseded or discontinued, only a handful of oil pumps were available when Pontiac discontinued the entire line several years ago. Fortunately, at least one company presently produces new Pontiac oil pumps, and its history is quite rich.

Melling Tool Company

The Melling family started Melling Tool Company in 1946, when it developed its M-10 oil pump—a stock-replacement unit for ’37 six-cylinder Chevrolet engines. Its first aftermarket high-volume oil pump was introduced in 1952 and revolutionized the industry. Many high-quality aftermarket oil pumps followed.

Melling remains well respected today for its world-class engineering, product development, and distribution capabilities. It operates 11 facilities in North America and Brazil, and supplies OE-spec and high-performance fluid pumps, including oil, water, and fuel for gas and diesel, transmission, and hybrid applications. It also offers a full line of camshafts and valvetrain components, cylinder sleeves, expansion plugs and bearings, engine hardware, and tools for the engine-building industry.

The oil pumps, intermediate shafts, and pickup-screen assemblies that Melling produces were created from original GM drawings. “This allows our components to fit the exact application,” says Mike Osterhaus, product development manager at Melling. “By applying our knowledge of pump design to the internal features of the housing and components, we can improve performance and durability. We don’t consider a Melling oil pump good enough unless it exceeds the expectations and specifications of the original it replaces.”

Melling began manufacturing its M-54-series oil pumps for Pontiac V-8s in 1963. “The original No. M-54, which was our standard-volume pump, rated at approximately 40 psi, was discontinued around 1990,” says Osterhaus. “We presently manufacture and 100-percent test four specific oil pumps for Pontiac V-8s at our Michigan facility. That includes our OE-replacement Nos. M-54D and M-54F, and Nos. 10540 and 10541 in our Select Performance line.”

He continues: “The M-54D oil pump is designed as a replacement for any 265-455ci Pontiac engine and uses the larger ¾-inch-diameter inlet opening. Its pressure bypass is set at 50 psi. The M-54F is a replacement for certain Ram Air and Super-Duty 455 engines. It uses a specific bypass valve that’s designed to increase maximum oil pressure by roughly 20 psi when compared to the M-54D. The volumetric displacement of the gear set we use in either is roughly 2 ci per revolution.”

Osterhaus is quick to point out that even though the pressure bypass valves actuate at 50 and 70 psi, respectively, it doesn’t necessarily mean that oil pressure within the engine will be exactly 50 or 70 psi.

“It’s dependent upon such variables as engine speed, bearing clearances, and oil temperature and viscosity. Actual pressure could be higher or lower depending upon the particular engine and where the oil pressure reading is taken.” When dealing with a typical Pontiac V-8 and production-bearing clearances, pressure at the gauge is usually 60 and 80 psi, respectively.

Melling’s Select Performance oil pumps were first introduced in the early ’90s and incorporate improvements to the pump design, displacement, tolerances, materials, and coatings. “Our Nos. 10540 and 10541 fit the same respective applications and bypass pressure settings as our M-54D and M-54F units. The tolerances and clearances of the Select Performance units are improved to maximize performance and reliability in high-performance applications,” Osterhaus says.

Butler Performance Pro-Series

Butler Performance is intimately familiar with the Pontiac lubrication system. “The Pontiac oiling system is very good, and the basic Pontiac oil pump is a decent design,” says David Butler. “The original pumps were sufficient for the intended applications, and they’re quite reliable—many went 100,000 miles or more without incident in their original engines.”

If there is a weakness within the Pontiac oil pump, Butler believes it’s the ball-type bypass valve. “If some debris or a small metal sliver gets lodged between the check ball and its seat, the ball may stick open. That can cause oil pressure to fluctuate, also routing some oil flow back toward the inlet side of the pump. Whether or not that actually affects performance in a typical street engine is unclear. It can mean disaster for a high-performance engine, however.”

Butler Performance has used and sold Melling oil pumps for many years. “Just as Melling states, we’ve found that the fit and finish of its Select Performance pump is better than the M-54 series unit,” says Butler. “We recently begun offering our own Pro-Series oil pump. We picked up where Melling left off, modifying its basic pump to further improve performance and reliability for high-performance applications, and then we bench-tested it to ensure complete functionality.”

David Butler says the company developed its Pro-Series pump to eliminate any chance of an oil pump-related issue on new engines. “Because it’s been pressure-tested, we know that it will operate consistently and reliably; that reduces the number of variables that could cause an operating issue at initial engine startup. We consider our Pro-Series pump as cheap insurance to prevent low oil pressure on initial startup, and we use it in many of the engines we build.”

Butler Performance’s offering begins life as an M-54F unit that is completely disassembled and re-machined. During the process, a lubrication groove is cut into the driveshaft bore and the driveshaft is micro-polished. The pump-gear pedestal pads are diamond-lapped and also feature a lubrication groove. The idler gear bore is honed and an oil weep hole is added to prevent oil cavitation—a condition where trapped air pockets collapse, causing irregular shock loads that can prematurely fatigue components.

Certain Pontiac oil pumps were equipped with a thick, cast bottom plate. “We’ve seen some of the thinner, stamped plates that are common on today’s pump flex with pressure as low as 20 psi, and that can have negative effects,” says Butler. “We use an extra-thick, cast bottom plate on our Pro-Series pump. It is diamond-lapped to improve sealing, and contains machined grooves to prevent cavitation and improve lubrication between the gear and plate.”

The bypass-valve ball and sealing surface of its Pro-Series oil pump are machined and blueprinted. “The bypass spring is tested to ensure consistency, and pressure is set to 75-80 psi at the gauge—though depending upon bearing clearance, it could be higher within the engine. We can shim the pressure relief spring to increase pressure slightly, or install a 60-psi assembly to reduce pressure, depending upon the engine’s needs. The finished pump is completely tested and includes a detailed flow chart,” Butler adds.

Along with an enlarged discharge hole, the total effect of Butler’s internal modifications also improves oil flow of the Pro-Series pump. “Maximum oil flow on a stock-type 60- or 80-psi pump with a stock pickup screen is usually 12-13 gallons per minute (gpm), and cavitation within the pump makes that output rather inconsistent,” says Butler. “Our modifications significantly reduce cavitation and increase maximum flow to 18-19 gpm, when combined with a good aftermarket pickup.”

Butler thinks that the Melling Select pump is adequate for street engines that operate at speeds less than 6,000 rpm. “We recommend our Pro-Series oil pump for almost any application, but highly recommended it for engines that will see more than 6,000 rpm or generate more than 550-600 hp. We’ve seen engines making more than 1,500 hp operate suitably using a standard Pontiac pump, but we begin suggesting other gerotor-type or billet dry-sump pumps when engines exceed 1,200-1500 hp.”

Oil Pressure Requirements

A common question from many Pontiac hobbyists is about oil pressure and just how much is required. “We generally feel at least 10 psi of oil pressure for every 1,000 rpm is the minimum requirement for reliable operation,” says Butler. “We recommend 20W-50 oil for our high-performance engines, and like to see hot-idle oil pressure between 30 and 40 psi. Pressure as low as 15-20 psi doesn’t necessarily present a risk as long as it isn’t a sign of other problems, but the amount of time it takes pressure to climb to 60 psi or more can put the bearings at risk on a quick-revving, high-performance engine.”

Butler says that since an engine with smaller-diameter main journals (3-inch) and shorter-stroke crankshafts (4.21-inch or less) is generally less stressful on the bearings, a 60-psi pump may provide adequate lubrication in a modified engine, but an 80-psi pump is a better choice. He says any performance engine with 3.25-inch-diameter main journals and/or a stroker length greater than 4.21 inches should use an 80-psi pump. “The greater oil pressure associated with the 80-psi pump improves the strength of the oil film, and better protects the bearings in large journal and/or long-stroke applications,” he adds.

Common hobbyist concerns when using an 80-psi oil pump in a street engine include excessive parasitic loss, bearing wash, and premature distributor and/or cam gear wear.

“We’ve never seen a noticeable performance loss from the added load,” says Butler. “Racers will sometimes run a 60-psi pump to reduce parasitic drag and free up a few horsepower. While that’s acceptable in a dedicated race engine that’s frequently torn down, it’s certainly not something we recommend for all engines.”

He continues: “We’ve run as much as 100-psi on some engines and have never experienced any bearing wash issues. Excessive distributor or cam gear wear can result, particularly with a bronze gear, but we consider positive cam-gear oiling a must when running a roller camshaft, and we found that it significantly improves distributor gear life.”

One area that many hobbyists overlook when selecting an oil pump for a particular engine is camshaft type. “Some of the aggressive hydraulic- roller-lobe profiles available today and the high-pressure valvesprings required to effectively maintain valvetrain stability can cause the roller lifter’s hydraulic internals to bleed down too quickly, and that can create a performance loss. In these instances, additional pressure (75 psi or more) is required to keep the hydraulic lifters working properly,” states Butler.

Conclusion

Pontiac oil pumps were designed to last the lifetime of the engine, and there are certainly many that are still functioning reliably in original un-rebuilt Pontiac V-8s. While a new oil pump is suggested during any rebuild, reusing an aftermarket unit during a subsequent rebuild is possible if it’s relatively new and looks to be in excellent condition after a thorough cleaning and inspection. Regardless of its visual condition, a new pump is absolutely required anytime debris has circulated throughout the engine, such as a bearing or camshaft failure, or any major engine malfunction.

No matter the situation that leads you to your next rebuild, you can rest assured that one of the options presented here is sure to fit your Pontiac V-8’s oiling requirements!