Originally written by Rocky Rotella for High Performance Pontiac magazine in the October 2006 issue. The original article and photo gallery can be viewed here.

Which came first, the chicken or the egg? It’s an ageless debate, lacking a definitive answer, yet both sides are strongly supported with opposing theoretical views. Many agree that its automotive equivalent is “Which is better for my Pontiac, manifold- or ported-vacuum advance?” And like the chicken/egg dispute, some hobbyists strongly favor one side over the other in every instance. But the truth is every combination is different, and rarely can any two be tuned identically.

Some hobbyists have no trouble grasping the concept of vacuum advance and the effects various vacuum sources have on it. Others, however, consider vacuum-advance tuning a form of black magic and oftentimes never fully realize its benefits. So what advantages does vacuum advance offer? Follow along as we test the different forms on our Pontiacs and discuss the results.

Spark Advance Basics

Typical engines generate torque by applying the expansion forces of combustion as leverage on the crankshaft. Maximum possible torque seems to occur when cylinder pressure peaks at a crank angle between 10-20 degrees after top dead center (ATDC). This allows the pressure to exert its force over the entire length of the crankshaft’s stroke. But since the crank is in constant motion, ignition must begin before top dead center (BTDC) for peak pressure to occur ATDC.

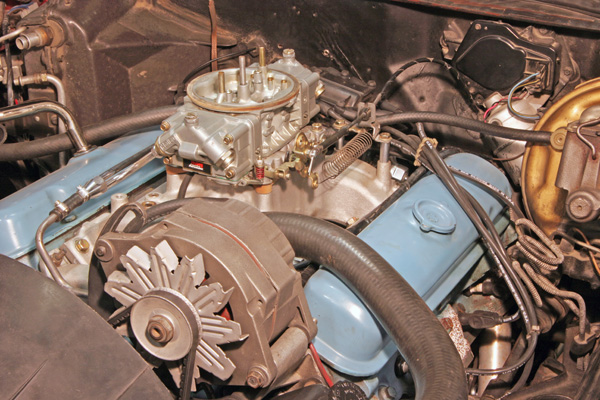

Our 1976 Trans Am test car.

A normal trip for most Pontiacs today includes a number of different throttle positions ranging from idle to full throttle. Rapid acceleration or heavy engine workloads typically require excessive throttle position to intensify combustion and increase output. Because the burn requires a fixed time, spark must start earlier as engine speed increases due to less available combustion time. Distributors mechanically advance spark lead in relation to TDC for maximum performance in these conditions.

The carburetor is designed to provide minimal amounts of fuel and air in light-load conditions such as part-throttle cruise. But because cylinder volume doesn’t change, the molecules within the chamber are not as tightly compacted, resulting in a less combustible mixture. Not only is such a mixture more difficult to ignite, the flame spreads slower, delaying peak pressure. For maximum performance in these conditions, spark must occur even earlier, sometimes in excess of 50 degrees BTDC.

Vacuum Advance Basics

A heavily loaded engine produces little vacuum while the highest vacuum levels occur at sustained light-throttle cruise. But for maximum efficiency in either instance, peak pressure must still occur in the desired ATDC range. A heavily loaded engine, however, will likely detonate with the high levels of spark lead a lightly loaded engine can tolerate, so a load-sensing unit that uses engine vacuum to advance spark in light-load conditions is added to the distributor. As engine load increases and vacuum levels diminish, vacuum advance reduces spark lead to lessen the risk of engine-damaging detonation.

Any engine that’s street driven can benefit from at least some vacuum advance.

AC Delco produced a number of vacuum advance units for GM, each with unique vacuum actuation points and/or maximum spark advance. Those used in original applications matched the engine’s vacuum levels and centrifugal advance curve. But because emissions were of great concern, some concessions were required.

Excessive spark lead in light-load conditions can generate the highest level of hydrocarbon (HC) emissions. In these instances, the flame front is quenched by a cooler surface, such as the cylinder wall, and the unburned and partially burned fuel and air molecules are emitted as HC. Engineers found that HC emissions could be limited by reducing spark lead in light-load conditions. This not only increased overall cylinder temperature, but also delayed the crank angle that the flame extinguished.

We tested on our ’72 and ’76 Trans Ams. Because both cars are driven regularly, idle quality and low-speed street manners receive as much attention as full-throttle performance. And even though 455ci engines power both, the two combinations are very different. See a full rundown of the specifications in the accompanying chart.

Prior to beginning the experiment, we determined the amounts of initial and total spark lead that the engines seem to perform best with. Using professional equipment, we carefully calibrated each distributor’s centrifugal advance curve. Over the course of several weeks and several hundred miles, we recorded engine vacuum levels and noted throttle response and overall performance in every driving condition without any vacuum advance whatsoever.

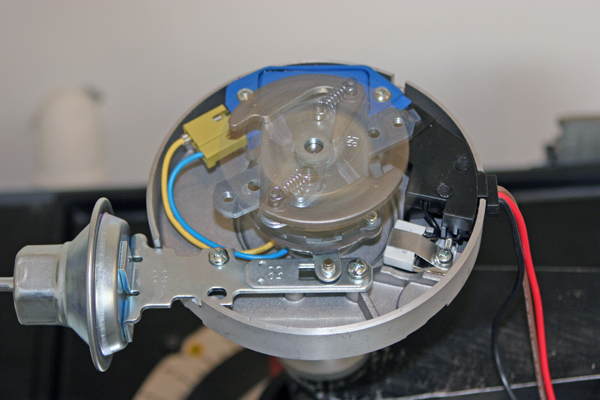

We Needed Crane's Adjustable Vacuum Advance Kit In One Instance. Offering A Wide Range Of Vacuum And Advance Settings, It Seems Most Beneficial When Tuning Radical Combinations. Installation Details Were Covered In "Opportune Timing," Which Appeared In The Jan. '04 Issue Of HPP.

Past testing indicates that Pontiac engines typically respond favorably to 12-16 degrees of vacuum advance, bringing total spark lead (initial plus centrifugal plus vacuum advance) into the 45-50 degree range at part throttle. Although some engines may tolerate even greater amounts without detonating, the effects appear to diminish with spark lead much beyond that.

After selecting vacuum-advance units that best complement our engines’ operating characteristics, we installed them and connected them to ported vacuum. We immediately noticed a dramatic increase in part-throttle response from each engine with roughly 15 degrees of vacuum advance, especially at sustained cruising speeds. Vacuum levels in those conditions jumped 1 to 1.5 inches, indicating improved engine efficiency. We also set both carburetors leaner, which certainly contributed to the fuel economy increase of nearly 2 mpg we saw from both vehicles.

Manifold-Vacuum Advance On The ’76 T/A

As strong as both Firebirds felt at part-throttle, we knew that manifold vacuum advance oftentimes improved idle quality. The ’76 Trans Am’s large flat-tappet camshaft idled rough and barely produced 8 inches of vacuum at 1,000 rpm. So we chose a stock-replacement vacuum-advance unit that operated with the least amount of vacuum hoping it would fully deploy at idle. However, there was little idle quality improvement. It wasn’t until we revved the engine and increased vacuum that we saw a 250-rpm increase in idle speed.

After resetting the idle speed and readjusting the idle-mixture screws, the initial road test proved very disappointing. Every time the clutch was engaged, engine vacuum dropped and the unit retracted, causing the engine to stumble severely at take-off. Once underway and vacuum levels rebounded, the engine surged violently while coasting or decelerating. It became apparent that the stock replacement unit wasn’t correct for this manual-trans-backed engine; an adjustable aftermarket unit was likely required.

Street testing the ‘76 Trans Am with various forms of vacuum advance.

The available advance of the aftermarket unit was limited to 14 degrees, and the vacuum-activation point was lowered considerably. Once installed and connected to manifold vacuum, idle speed increased as soon as the engine fired. After resetting the idle speed and readjusting the mixture screws, vacuum increased about 3 inches. The large camshaft seemed much tamer, and idle quality was smooth and stable. Additionally, the exhaust note gained a pleasant, finely tuned sound.

Subsequent road tests proved that the engine was largely unaffected by clutch engagement, and acceleration was extremely smooth and effortless. Surging, however, was still present, although not nearly as severe. The most logical corrective action was to further reduce vacuum advance. After a number of different static initial and vacuum-advance settings, we ultimately arrived at 14 and 12 degrees, respectively. This limited surging to extreme driving conditions and reduced idle vacuum by 0.5 inches, but there was no detectible loss in idle quality or low-speed street manners.

A ported vacuum source receives its vacuum signal from this slot found in the primary bore, which is covered by the throttle blade at idle. Once acceleration begins, the slot is exposed to manifold vacuum and the vacuum signal above and below the throttle blades equalizes.

Manifold-Vacuum Advance On The ’72 T/A

After moving the ’72 Trans Am’s vacuum-advance unit from ported vacuum to manifold vacuum, idle speed immediately increased about 200 rpm. After the preliminary adjustments, idle quality noticeably improved, and vacuum jumped roughly 1.5 inches. The load generated by placing the automatic transmission into gear seemed to affect the engine less, another indication that it was operating more efficiently on the available fuel mixture.

A definite improvement on idle, initial take-off, and light-throttle acceleration characterized the overall effect of manifold-vacuum advance over ported. We did not, however, expect or notice any real difference in part-throttle response over ported vacuum. What we did discover, though, was a smoother transition when reapplying the throttle after coasting at speed, likely caused by the spark lead that manifold vacuum advance maintains while coasting and decelerating.

Modifying The Carburetor

Whenever an engine is modified to increase power, the carburetor needs to supply additional fuel. Although most are familiar with the metering jet and/or rod changes that affect the primary and secondary circuits, many often overlook the idle circuit. In instances where engine modifications are limited, the original carburetor may supply just enough idle fuel to get by. But in today’s world where hobbyists commonly install smog-era carburetors onto high-performance engines that deviate greatly from any original application, idle mixture is oftentimes severely lean. This may be why excessive amounts of manifold-vacuum advance seem effective in certain applications.

Knowing that the idle circuit of the Quadrajet on our ’72 Trans Am had never been modified, we sent it to Cliff’s High Performance in Mount Vernon, Ohio, for proper calibration. Upon its return and reinstallation, we found that the mixture screws had a greater effect on overall idle quality, throttle response noticeably increased, and the transition from idle circuit to primary was less noticeable. But we found something else while verifying the static initial setting that was totally unexpected.

Other Than The Camshaft, The Only Non Original Component On Our '72 Trans Am Is This Rare '71 455 H.O. Quadrajet. For Increased Airflow, These Unique Units Lack The Traditional Booster Rings Found In Other Q Jets. Like Many Carburetors Of This Era, Its Idle Circuit Was Already Lean To Combat Emissions, But Once We Added A Slightly Larger Camshaft, The Mixture Screws Had Little Effect. So It Was Sent To Q Jet Guru Cliff Ruggles For Recalibration.

When the vacuum-advance unit was disconnected, idle speed decreased slightly, but actual idle quality changed very little. It appeared that the additional idle fuel allowed the mixture to burn more efficiently with less spark lead, and that manifold-vacuum advance was not totally necessary. This prompted us to readjust the carburetor settings and reconnect the vacuum-advance unit to ported vacuum for further testing. The result included a strong, stable idle and seamless transitions without any effect on economy.

What We Learned

After logging several hundred miles with both Firebirds in their final states of tune, we are completely satisfied with the results. We were able to tame a radical camshaft and dramatically improve temperament with manifold-vacuum advance in one combination. In these instances, the long-duration camshafts required for high-rpm operation have excessive valve overlap, which tends to dilute the incoming mixture with residual exhaust gas. Additional spark lead provides extra time for a more complete burn of the mixture in each cylinder.

We Tapped Into The ECM Of Our '01 Trans Am To See If Tuning Practices Had Changed With Current Technology And Emissions Regulations. Using An OBD II Compatible Diagnostic Scan Tool, We Found That At Normal Operating Conditions, Our LS1 Idled With 22 Degrees Of Advance, And It Peaked At 38 Degrees At Part Throttle. Consider That The Cylinder Heads Of These Engines Are Designed For The Quickest Possible Burn, As You Can See In This LS1 Chamber Shot With Its Heart Shape And Spark Plug Biased Toward The Exhaust Valve, Among Other Features. As A Result, Maximum Full Throttle Performance Requires Just 28 Degrees Of Advance.

We also found that relatively stock combinations with limited modifications do not always benefit from manifold-vacuum advance, especially if the carburetor’s idle circuit has been modified. It appears that in these instances manifold-vacuum advance will not always improve street manners but can smooth idle. Ported-vacuum advance can then be used to improve part-throttle response and overall fuel economy. If the original carburetor is unmodified or a different carburetor is used entirely, manifold-vacuum advance will likely provide noticeable improvements in all operating ranges.

Conclusion

There is one constant generality about vacuum advance that likely applies to every combination: A suitable amount (whether manifold or ported) can noticeably increase part-throttle response without any negative aspects. But because most of our engines are modified in some manner, neither form is necessarily “correct” for any vehicle. Since vacuum advance offers such distinct advantages for any car driven on the street, we suggest experimenting with both forms to determine which works best for your specific application. Once you find the right combination, you’ll wonder why you waited so long to perform your own vacuum-advance experiment!