When it comes to Pontiac’s Super Duty 455, it’s a subject I take quite seriously.

I’ve spent the past 30 years (and probably more!) researching the SD-455’s path though development, production, and cancelation. In that time, I’ve had the chance to speak with a number of those at Pontiac directly involved with the SD-455 program. I’ve also been able to collect a great number of internal SD-455 documents and memos that have clarified some of the conjecture surrounding the engine. (Please contact me if you have any bulletins or documents you’re willing to share!)

This 1973 press photo of Pontiac’s race-bred Super Duty 455 in the assembly plant is iconic. (Photo courtesy of General Motors)

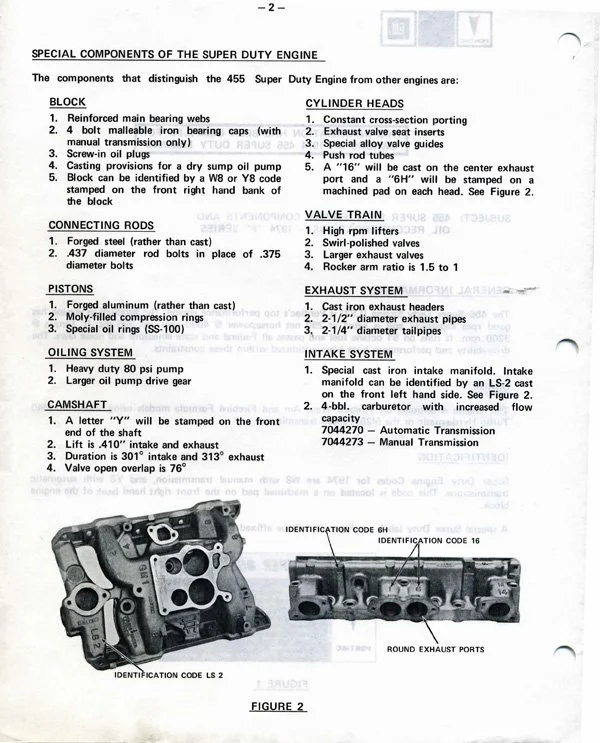

Most Pontiac enthusiasts know that the SD-455 was equipped with a unique hydraulic flat-tappet camshaft. But how does it differ? To reduce operational load (and resultant wear) associated with the 80-psi oil pump, Pontiac engineers revised the helix angle of the camshaft and distributor gears (which in turn, drive the oil pump) by incorporating an undersized drive gear on the camshaft and an oversized driven gear on the distributor—a feature first introduced on the tunnel-port Ram Air V.

This side-by-side comparison of a standard Pontiac V-8 camshaft (left) and the unique SD-455 camshaft (right) with corresponding distributors illustrates the size differences in drive/driven gears.

Unrelated to gear sizing, the SD-455 camshaft remains a topic of discussion within SD-455 circles. Why? It’s because Pontiac changed its specifications from 308/320 degrees to 301/313 after preliminary 1973 model year information was distributed. Most hobbyists know that the SD-455 camshaft did change during the 1973 model year, but the real question is when? Some argue that a handful of production SD-455s received the 308/320 grind, but after decades of painstakingly searching I’d found no proof of that.

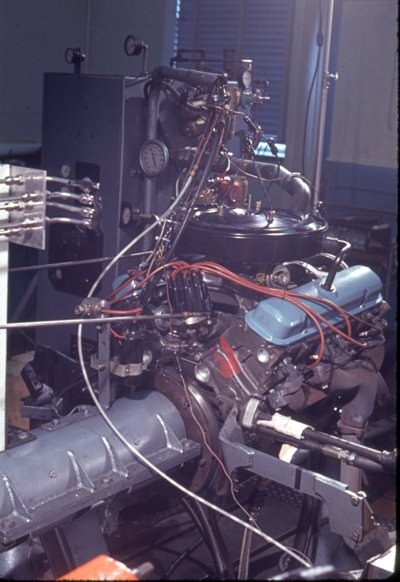

A developmental SD-455 on the dyno cell at Pontiac Engineering being tested for power output.

Let’s first address why the SD-455’s camshaft specifications changed. During SD-455 development Pontiac engineers decided best general performance was achievable with valve timing (308/320 degrees) and lobe lift (.470-inch with 1.5:1 ratio rocker arm) identical to the successful number-041 that camshaft whiz Mac McKellar designed for the Ram Air IV. The SD-455’s undersized drive gear required a new camshaft, which was numbered 480737 and identified by a “K” stamped onto the snout.

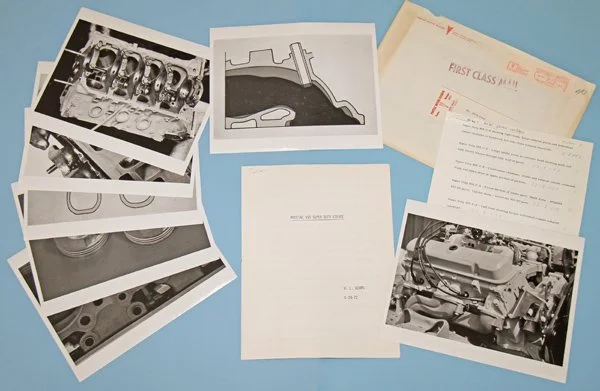

At Pontiac’s 1973 Long Lead Press Preview, Pontiac Engineer Herb Adams introduced the SD-455 to the motoring world. Transcripts of his speech and press photos of what made the SD-455 unique were available to writers.

At its 1973 Press Preview in June 1972 Pontiac touted the SD-455’s prowess and technical specifications. Rated at 310 hp at 4,000 rpm and 390 lb/ft at 3,600 rpm, slated availability included the A-car (LeMans, GTO, and Grand Am), G-car (Grand Prix) and F-car (Firebird). Magazines of the time were buzzing with Pontiac excitement and at the onset of 1973 model year production consumers hurried to dealership showrooms to order their Super Duty-powered Pontiacs. They found, however, that the SD-455 was on Hold status.

This page from the 1973 Pontiac Sales Manual (aka Dealer Album) outlines what makes the SD-455 so potent. It refers to the special camshaft, which was the “K” grind with 308/320 degrees of duration.

Former Pontiac engineer Skip McCully—who was part of the SD-455 development team (along with Herb Adams, Tom Nell, and Jeff Young)—was tasked with seeing the SD-455 into production. He explained to me that GM established its own 1973 model year emissions standard, which was slightly cleaner than the EPA’s 1973 federal standard. The difference provided a “cushion” to account for the production variances and general wear that could affect emissions to ensure that 100% of the engines its divisions remained emissions compliant over their entire service life.

Every 1973 model year vehicle was tested for emissions compliance by General Motors. EPA certification of the SD-455 was delayed because of a required camshaft change. (Photo courtesy of General Motors)

McCully shared that the SD-455 with the 308/320 camshaft was compliant with the EPA’s 1973 federal standard, however, it was unable to meet GM’s internal standard. Pontiac was forced to delay the SD-455’s release until engineers could find a solution and recertify it. With customers anxiously awaiting the highly-publicized mill there simply wasn’t time to develop a new camshaft. McCully and team had little choice but to grab the closest proven performance option—a 744-spec camshaft with 301/313-degrees of duration and .407-inch valve lift. The number 493323 (stamped “Y”) camshaft was created for the application, which consequently impacted power output.

Pontiac changed the SD-455’s camshaft in November 1972. Service literature was updated to include the “Y” grind.

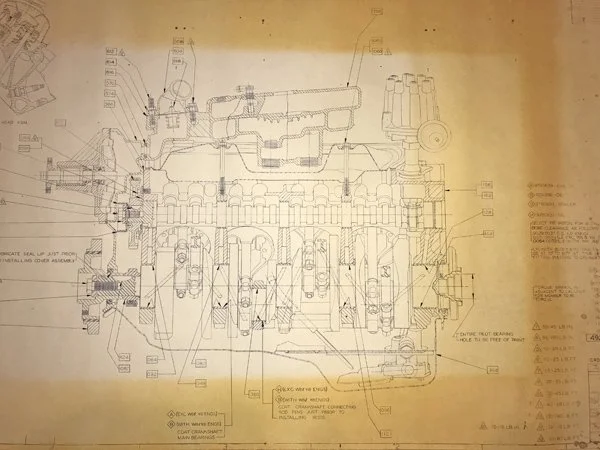

After years of attempting to determine when Pontiac changed the SD-455’s camshaft specification, it wasn’t until some key internal Pontiac documents came my way that we—as hobbyists—now know that timeframe. I can confirm from its blueprint that the 493323 “Y” camshaft was released for production in late-October 1972. Pontiac then published revised SD-455 power ratings on November 3, 1972. Horsepower decreased by 20 while torque increased by 5 lb/ft to a total of 290 hp at 4,000 rpm and 395 ft-lbs at 3,200 rpm.

For identification when in service, Pontiac identified its camshafts with a stamped character on the snout. Notice the “Y” at the 1:00 position. It identifies this particular camshaft as the 301/313-degree number-493323 that was installed in production SD-455s.

With EPA certification pending, all indications pointed to a December 1972 release of the SD-455. In anticipation of EPA approval, Steve Oakley, a Pontiac manufacturing supervisor ordered from the foundry a production run of Super Duty blocks, cylinder heads, intake manifolds, and other components in mid-November 1972. Then Pontiac was hit with a major blow. The EPA determined that Pontiac was using an emissions defeat device to override EGR in certain conditions on all its 1973 V-8s. Pontiac was required to take corrective action and then recertify all its V-8s by mid-March 1973. That meant that the SD-455 had to be recertified yet again.

I was fortunate enough to acquire a number of original SD-455 blueprints from a former Pontiac engineer. They have been an invaluable resource for documenting the development process. The large rolls measure approximately 3-feet tall by 8-feet wide!

The SD-455 had been delayed so long that waiting consumers grew frustrated. Some canceled orders or purchased other vehicles. Pontiac’s then-General Manager, Martin Caserio considered cancelling the SD-455 program entirely but ultimately relented because his division already had components on hand and there were open purchase agreements with outside suppliers for others. Caserio’s stipulation was making it available in the Firebird only. As history played out, the SD-455 was finally released for production in May 1973 and reached the Firebird assembly line in early June. A total of 295 Super Duty Formulas and Trans Ams were produced in what remained of the 1973 model year. About 1,000 more SD-455s were produced in 1974 before it was cancelled for 1975 in lieu of even stricter emissions standards and greater emphasis on fuel economy.

This 308/320 degree SD-455 camshaft (number 480737) was installed in an SD-455 engineering mule used for high-speed testing at GM’s Desert Proving Ground. Note the small drive gear.

For years I’ve searched for anyone who may have owned or received an SD-455 “K” camshaft (308/320) to no avail. I was certain that developmental examples were produced, but from the EPA-influenced timeline, its stands to reason that no production SD-455 could have ever legally received the 480737 from the factory. And while the 480737 appeared in Pontiac parts manuals for a short time, it seems all orders for the cam went unfilled. Even famed Pontiac builder, Nunzi Romano of Nunzi’s Automotive in Brooklyn, New York, who had deep connections within Pontiac told me that he wasn’t able to get his hands on one.

The “480737” part number was hand-scribed into rear journal of this particular SD-455 camshaft.

Just when I’d all but written off ever seeing a real 041-spec SD-455 camshaft (480737) in my lifetime, one recently showed up on my doorstep! Fellow SD-455 enthusiast Michael Scicluna connected me with Rick Annis—a former engineer at GM’s Desert Proving Ground—who salvaged a developmental SD-455 used for high-speed testing from the scrapper in the mid-1980s when GM purged aged inventory. Inside his Pontiac Engineering-assembled SD-455 was the illusive 480737 camshaft!

Because the 480737 shared its valve events with the 041, it’s not surprising to find a “T” stamped in the snout of this camshaft at the 9:00 position. The “K was hand-scribed as was additional information, which suggests that this 480737 started as a genuine 041 camshaft that Pontiac modified (converted) when a “K” was required for a preproduction SD-455 application. Did Pontiac ever produce on with a stamped “K”? We may never know.

Rick sent me a few text messages with photos of the well-used cam. I simply couldn’t believe what I was seeing. Here was the camshaft I’ve spent decades searching for! Rick was selling the SD-455 to Michael for his project and Michael offered to loan the 480737 unit to me so I could photograph it for my files. (Thank you, Michael!) Once in hand, I was flooded with thoughts of how many 480737 cams could even be left, but more importantly how truly special this piece of SD-455 history is. I’m privileged to be sharing it with you!

What are your recollections of the Super Duty 455?